The plan do check act approach achieves a balance between the systems and behavioural aspects of management. And everyone adopts it using the support of a coach or their leader to help them implement improvements daily.

Plan Do Check Act Pdca Cycle

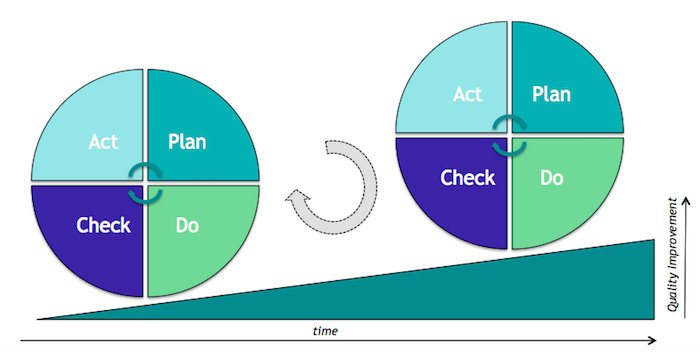

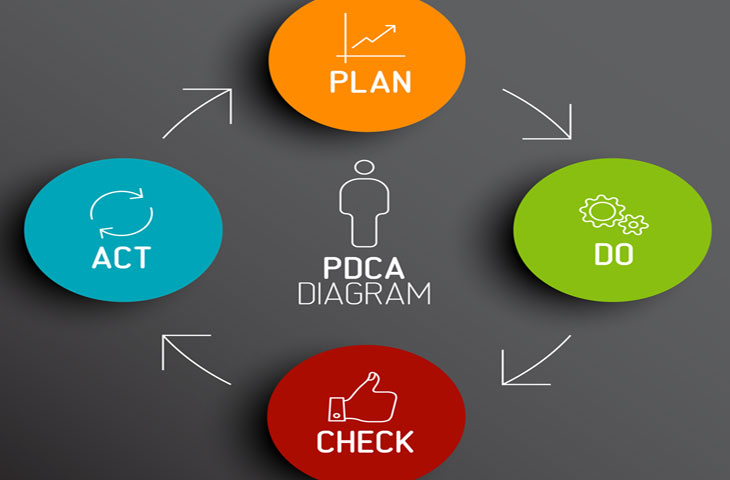

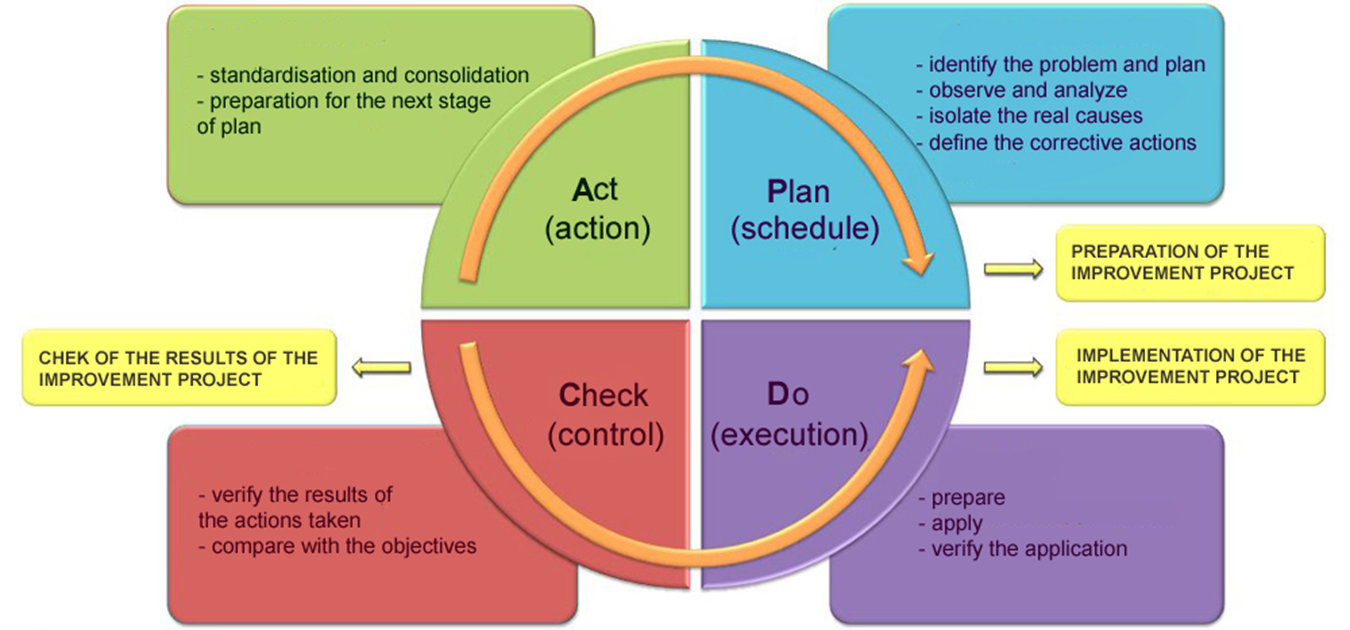

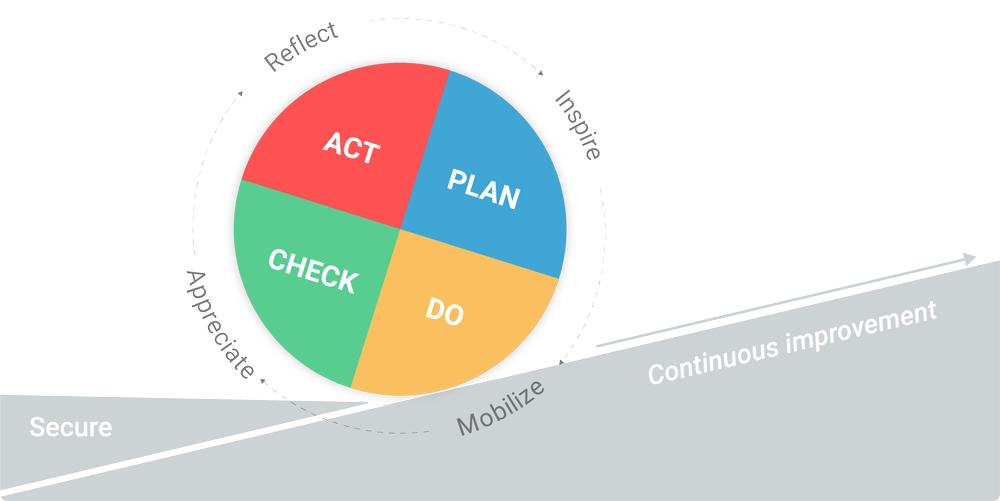

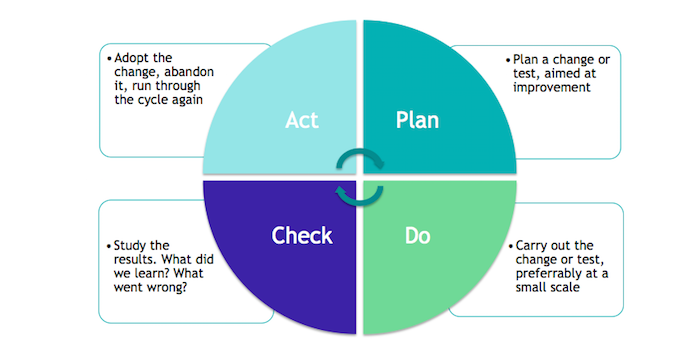

Plan do check act. First proposed by walter shewhart and later developed by william deming pdca cycle became a widespread framework for constant improvements in manufacturing. Deming used the concept of plan do study act pdsahe found that the focus on check is more about the implementation of a change. Demings focus was on predicting the results of an improvement effort studying the actual results and comparing them to possibly revise the theory. All other lean tools are only on top of the pdca. The plan do check act cycle figure 1 is a four step model for carrying out change. The plan do check act cycle is a reflection of this.

It was used to improve the production process in the us. It is also known as the deming circlecyclewheel the shewhart cycle the control circlecycle or plandostudyact pdsaanother version of this pdca cycle is opdca. Think about where you are now and where you need to be. Plan do check act or pdca is one of the key elements in lean manufacturing or for that matter in any kind of improvement process. The plan do check act pdca cycle also known as the deming wheel or the deming cycle is an iterative method for continual improvement of processes products or services and is a key element of lean management. The pdca cycle is considered a project planning tool.

During world war ii. Just as a circle has no end the pdca cycle should be repeated again and again for continuous improvement. It also treats health and safety management as an integral part of good management generally rather than as a stand alone system. The pdca cycle is a four step problem solving iterative technique used to improves business processes and bring about change. It is an essential part of the lean manufacturing philosophy and a key prerequisite for continuous improvement of people and processes. In my view it is the most basic framework for any kind of change.

Plan do check act can be used for many different scenarios. The plan do check act pdca cycle also called the deming cycle is a four step approach to problem solving that allows you to test various solutions to a problem to identify the most effective solution before implementationthe cycle can be refined and repeated time and time again for continual process improvement cpi and can be used by any department from quality to accounting to marketing. In my experience most lean projects in the western world fail not because they do not have some detailed tool but because the pdca is neglected. Systematic plan do check act process. Plan do check act pdca template for powerpoint is a fully editable template based on the pdca cycle developed by w. Introduction explained briefly plan do check act cycle is a model for carrying out change.

Pdca plandocheckact or plandocheckadjust is an iterative four step management method used in business for the control and continuous improvement of processes and products. In fact where theres a problem it should be used to eliminate it.